Omnichannel fulfillment

An omnichannel fulfillment strategy can simplify your supply chain for increased revenue and profitability. By centralizing how you store inventory and fulfill customer orders, you can optimize landed costs, improve customer satisfaction, and scale into new online sales channels.

What is omnichannel fulfillment?

Omnichannel fulfillment is a retail strategy that integrates sales and distribution channels for unified supply chain management. It streamlines the tactics of multichannel fulfillment, where sales channels are managed independently.

With omnichannel fulfillment operations, you centralize your supply chain resources under one system. Many ecommerce companies sell products on multiple channels, like online stores, mobile applications, marketplaces, and retail-partner websites. Each channel may have different requirements, but the fulfillment processes are managed together for efficiency (especially upstream).

You may also have what’s known as a blended strategy. This is where you mostly use omnichannel fulfillment, but have a few channels that stay separate. Fulfillment by Amazon (FBA) is a common example. Brick and mortar retailers typically have their own network distribution requirements, too.

Omnichannel fulfillment vs. multichannel fulfillment

Many ecommerce companies already use omnichannel fulfillment processes, but you may find areas where you can streamline further. Explore the differences between omnichannel fulfillment and multichannel fulfillment to discover how you can improve your operations.

Centralizing your supply chain

Switching to an omnichannel fulfillment strategy requires digital and physical change management. First, you have to integrate data from multiple channels into a single system. Then, you need to consolidate your physical supply chain around strategic geographic locations that allow you to optimize customer deliveries.

Depending on your business’ complexity, here are some omnichannel fulfillment services and tactics to consider.

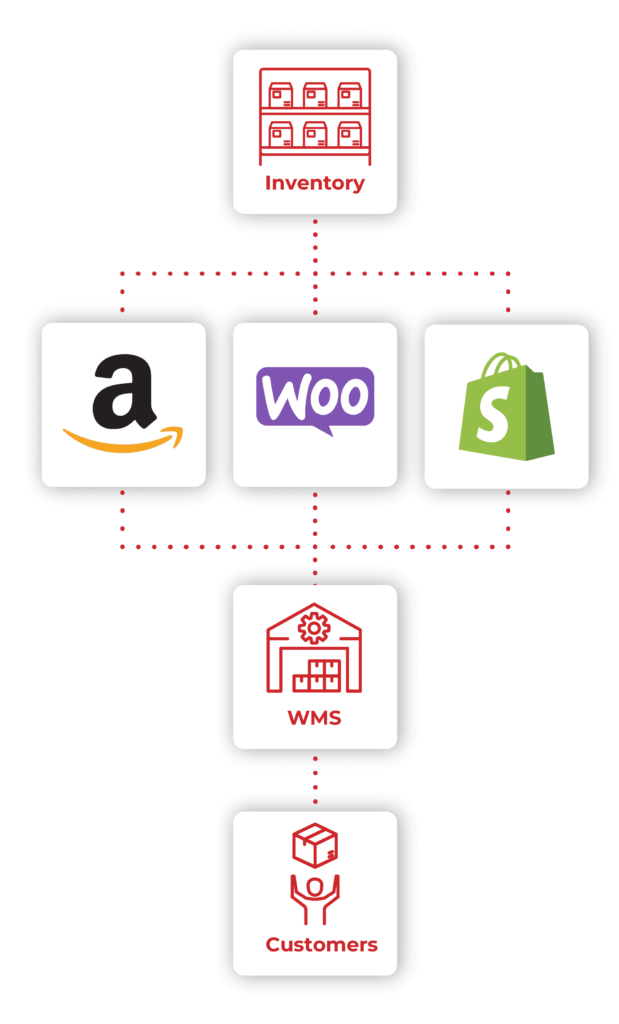

Sales integrations

Connect all sales channels to a warehouse management system (WMS). The integration delivers real-time pick and pack notifications to warehouses to speed up fulfillment.

Stock allocation

Move stock to centrally located warehouses so you can fulfill orders across all sales channels more quickly and efficiently. This limits cash investments in disconnected warehouses.

Centralized data

Unify your supply chain management systems to access larger datasets and find deeper insights. A centralized 3PL may offer additional insights based on their operations.

Inventory management

Use your new frameworks to optimize inventory for growth. With consolidated stock and better data, it’s easier to plan orders, negotiate with suppliers, and introduce new items.

Shipping discounts

Unlock volume discounts with centralized warehousing. You may also improve delivery times to meet consumer expectations. More items in fewer places make it possible.

Reverse logistics

Streamline returns and exchanges through a single warehouse. An omnichannel approach to item disposition may increase your chances of reselling returned products.

Satisfying customer expectations on any channel

Successful omnichannel fulfillment can make it easier to meet customer expectations and earn the satisfaction and loyalty that are so crucial for your growth across all sales channels.

It can also motivate customers to advocate for your business in reviews or on social media, which can increase your reach and revenue while reducing the costs required to gain new customers.

Fulfill orders quickly

Omnichannel fulfillment ensures there are no gaps in order notifications, pick and pack services, and shipping. This saves valuable hours so you can get items to customer addresses on time.

Improve order accuracy

Consolidation improves visibility and insights to drive continuous improvements. If you work with an omnichannel 3PL, your customers may benefit from much higher accuracy rates.

Optimize inventory

With all of your inventory in one system, it’s easier to run SKU analyses. Align supplier orders with demand, so you can provide the products your customers love without overspending on stock.

Maintain brand consistency

Omnichannel fulfillment provides a consistent customer experience across product descriptions and brand messaging. And, centralized customer support can share reliable answers about items and orders.

Cross channel fulfillment tactics

Omnichannel fulfillment reduces touch points across your supply chain, but some of your tactics may vary as items move downstream.

That’s because ecommerce channels can have different requirements for picking, packing, and shipping, especially if you sell on online marketplaces or other retailer websites.

For example, warehouse teams need to align with requirements for multiple selling channels. Packing slips, labels, and other marks may need to conform to those specific requirements. Return policies may vary across partners, creating reverse logistics complexities. This means your customer communication may vary based on order fulfillment partnerships and processes, too.

System integrations can help. These data exchanges are typically seamless, but some may require specific or unique information. Setting up infrastructure and automations could take extra time upfront, but would pay off during order lifecycles.

A blended strategy is common for both small and mid-sized businesses and enterprise brands. If you work with a 3PL, the scalability of omnichannel fulfillment services could help mitigate the increasing complexity that may come with growth.

Fulfillment by Amazon

If you use Fulfillment by Amazon (FBA), you probably have separate inventory and logistics requirements to deal with. FBA isn’t technically part of an omnichannel strategy because Amazon controls your fulfillment optimization, but you can still unify your other selling channels.

You can also use an FBA alternative to capture the opportunities of the marketplace, while driving overall operational efficiency. 3PL fulfillment centers may be able to provide greater storage scalability and transparent pricing to help you meet shifting demand across customer orders, including from Amazon. This approach would let you still reap the benefits of omnichannel fulfillment.

Growing with omnichannel fulfillment

Omnichannel fulfillment strategies provide a robust foundation for scalable growth. Many ecommerce companies use the efficiency and flexibility to increase order volumes, launch new channels, and diversify into brick and mortar locations.

Physical store requirements

Selling in physical stores can multiply your reach and revenue, but it creates supply chain complexity. Instead of centralizing inventory management like you do with omnichannel fulfillment, you have to separate some of your stock. This also requires forecasting stock allocation and coordinating order fulfillment.

If your brand has its own stores, consider setting up processes for in-store returns of online purchases, known as buy online, return in store (BORIS). That offers a level of convenience that some of your customers will likely appreciate.

But, depending on how you manage inventory, you may be able to move returns back under your omnichannel fulfillment operations after they leave your store. In this case, you would accept returns in store and send them to your main warehouse. Then, you could list the items across other selling channels again.

Retail partnership requirements

Most ecommerce companies don’t open their own stores, though. They partner with existing brick-and-mortar retailers to grow into offline channels. These retailers have highly detailed agreements, and they’re strict about compliance. As a partner, you’re responsible for helping maintain their established brand image.

You or your order fulfillment vendor may have to provide their systems with complete inventory visibility. This lets your partners see that you can satisfy their orders with timely delivery to their retail locations.

Partnerships may also require diversifying omnichannel logistics to align with their transportation networks. If they sell your products on their websites, you may need to further separate inventory and ship items to another order fulfillment center in their network.

Outsourcing omnichannel order fulfillment to a 3PL

The details of omnichannel order fulfillment processes may be challenging for your company to manage. For many leaders, outsourcing makes the most sense. The right partner can help you quickly realize the benefits of an improved fulfillment strategy.

Customer satisfaction

An experienced 3PL can help you align with industry demands, optimize inventory management, and minimize landed costs. They have precise warehouse processes and long-term carrier relationships to handle any fulfillment needs.

Operational efficiency

Speed and accuracy are vital to customer satisfaction. A high-quality 3PL is set up to ensure fast picking, packing, and shipping across all channels. Centralized operations mean your customers get the same high-quality experience they expect from you, no matter how they shop.

New sales channels

Growth opportunities are exciting, but they present risks. If you don’t scale efficiently, you could lose capital investments and disappoint customers. An experienced 3PL offers agility, labor resources, and technological infrastructure so you can grow across multiple channels.

Brick and mortar

Growth opportunities are exciting, but they present risks. If you don’t scale efficiently, you could lose capital investments and disappoint customers. An experienced 3PL offers agility, labor resources, and technological infrastructure so you can grow across multiple channels.

Finding the right omnichannel 3PL

If you’re ready to outsource omnichannel fulfillment, consider this list of questions to interview prospective 3PL partners and discover which one is best for your business.

Multichannel support

- What integrations does the 3PL offer?

- Can they support Amazon fulfillment?

- Can they support brick-and-mortar fulfillment?

- Will you have real-time inventory visibility?

- What other technology does the 3PL use?

Growth

- How does the 3PL support scalability?

- Are contracts flexible when you grow?

- How does the 3PL ensure labor availability?

- Do they provide volume discounts?

- Is pricing clear and transparent?

Performance

- Does the 3PL have strategically located warehouses?

- What is their fulfillment process?

- How does the 3PL manage reverse logistics?

- How do they limit shrinkage?

- What cybersecurity does the 3PL provide?

- What is the 3PL’s accuracy rate?

- How do they handle exceptions?

- Do they offer guarantees?

Work with Haulmax Fulfillment

At Haulmax Fulfillment, we can help your business create a successful omnichannel fulfillment strategy. With fast, accurate distribution backed by accuracy guarantees, our team is here to set you up for success.

Sales integrations

Integrate any sales platform with our WMS.

Inventory visibility

See real-time item availability for all channels.

Scalability & growth

Enter new channels with strategic support.

Fast receiving

Get dock-to-stock receiving in two business days or less.

On-time shipping

Fulfill orders with 2-day shipping to 96% of the U.S.

Accuracy guarantees

We get it right or make it right at no cost to you.

Fulfill orders from any channel within two days

Haulmax’s fulfillment centers are strategically located to provide you with a fast, cost-effective omnichannel order fulfillment process.

Sidestep the higher costs of broad distribution networks and urban congestion by centralizing your inventory with us while enjoying all of the benefits that the omnichannel fulfillment model has to offer.

Reach out to Haulmax today to see how we can help your business with omnichannel fulfillment.